Deep inside the belly of Corti Brothers in East Sacramento, past the double doors marked “employees only,” past the walk-ins and shelves of goods and hustling employees, a piercing klaxon is sounding in the kitchen. Is it a fire alarm? Has a miscreant entered through a back door to burgle a jar of vintage marmalade? Much more dire: The cheese ravioli filling in the ravioli machine hopper is getting low.

It’s a (perhaps unnecessarily) dramatic warning from a magnificent, huge (27 by 3 1/2 feet) ravioli machine. This machine, which in the 1970s replaced a machine that dated to the ‘20s, creates 2,400 boxes of Corti Brothers ravioli a month and up to 7,000 during the holidays. On their website, Corti’s touts the ravs as “the oldest continuously produced food product in Sacramento”; they have been in production since the store’s inception in 1947.

The ravioli production line is attended by up to eight Corti Brothers employees at any one time. One, kitchen manager Eddie Enriquez, is wrestling with a 50-pound wad of pasta dough, as he does the initial flattening and flouring that will yield the stack of folded-over sheets thin enough to be fed into the wringers of the machine.

This is Enriquez’ second time leading a ravioli run while head ravioli maker Andrew Cordero is temporarily indisposed — the only production days he says that Cordero has missed in 40 years. Other employees are feeding the top and bottom sheets into the machine, watching the dollops of filling going onto the bottom sheet to patch any dough gaps, and rapidly using box-sized spatulas to load up exactly 48 tasty little nuggets in each iconic Corti Brothers box.

Cranking out the ravs

During a visit a week prior when the machine is at rest, General Manager Rick Minderman explains that they had explored the option of buying a new, more compact ravioli maker. It would have taken up 80 percent less space in the kitchen, but it could only make larger ravioli, skewing the desired pasta-to-filling ratio, and would have to be packaged in unsightly bags.

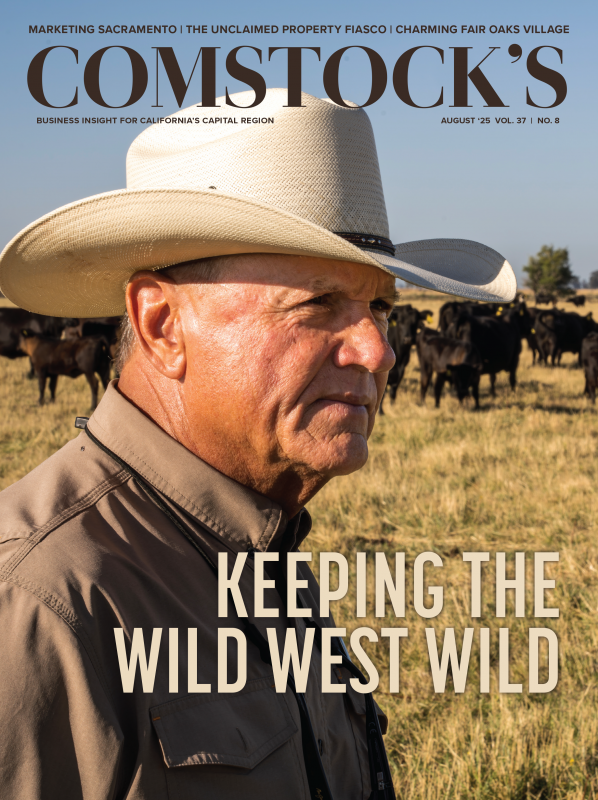

Workers turn out spinach-ricotta ravioli on a custom,

made-in-California machine at Corti Brothers in East Sacramento.

(Photo by Gabriel Teague)

Cordero is responsible for the newer ravioli varieties that were added to the original two (beef and cheese); he created the holiday, spinach and ricotta, chicken and pancetta, and mushroom flavors.

About the extremely popular holiday flavor, Cordero said it was initially created out of necessity when he had “turkey left over from Christmas and Thanksgiving dumped on my front doorstep. Butchers went ‘ding dong’ and ran. I would take it off the bone, roast it, make the filling. Then when ‘holiday’ would have to be made throughout the year, it morphed into boneless, skinless thigh meat.” The holiday ravioli’s filling has a 60/40 ratio of poultry and beef.

The mushroom flavor is labeled “di magro,” which is an Italian designation for meatless food; Cordero touts its “huge” porcini flavor. Minderman is partial to the chicken and pancetta and says he’s celebrating his granddaughter’s second birthday with a family lunch of Corti Brothers Pugliese garlic bread, salad and, of course, ravioli. “They always request it. Kids love it.”

‘So goldarned good’

Another thing kids love is candy, although perhaps not some of the sophisticated flavors that Kobasic’s Candies is known for, such as a balsamic vinegar “kruffle” (Kobasic’s cute variation on a ganache-filled truffle) or the bittersweet 86 percent cacao. Kathy Kobasic says that a local cardiologist sends his patients in for the latter candies, touting the antioxidant properties of cacao.

Kobasic’s, despite being a candy store since “only” 2003, has a rich history. Jim Kobasic, the owner and lead candymaker, comes from a family of candy makers that dates back to the 19th century. His grandfather, Joseph Sayklly, who came from a Lebanese candy-making family, immigrated to the U.S. and started the candy store Sayklly’s in Michigan’s Upper Peninsula in 1906; it’s still open today.

Kathy Kobasic, co-owner of Kobasic’s Candies in South Land Park,

says these salted caramel “kruffles” are among the shop’s best

sellers. (Photo by Gabriel Teague)

Price Club merged with Costco in 1993 and then became just Costco in 1997; the transition was a bumpy one for the Kobasic’s team, which by this time included the fourth generation (daughters Kathy and Nancy). Kathy says, “We were there during the transition from Price Club to Costco and decided, ‘That was interesting, and thank you; I’ve been there and done that.’ Now we just have our own little tiny shop.” They opened Kobasic’s Candies 22 years ago and have sold their candy there exclusively ever since.

Kobasic’s is open seven days a week, and Kathy says that business is good. They make 17 varieties of caramels, the best-selling of which is the salted vanilla. They also sell perishable and refrigerated “kruffles” and even a spicy coconut lime caramel that Kobasic the elder created when he had the song “(Put the Lime in the) Coconut” stuck in his head.

Towards the end of the interview with Kathy, Jim emerges from the back, where he’s been “krafting” kruffles. When asked what’s the hardest chocolate to make, he says, “The French vanilla is the hardest — making sure the egg doesn’t curdle. If it wasn’t so goldarned good I wouldn’t make it.”

How the (Taiwanese) sausage gets made

Luke Chang started producing Taiwanese sausages for sale in 2002 and then went on to open Southside Park neighborhood treasure Taiwan Best Mart in 2012. Last year, Chang wanted to retire, so the family sold Taiwan Best Mart in May 2025, and Luke’s daughter Christine took over the production facility, which still produces food prepared and sold in the cafe, now under the name Hoja Foods.

Christine Chang cooks at Taiwan Best Mart in 2021. (Photo by

Steve Martarano)

Hoja Food’s current offerings are five flavors of sausages (original, lean, rice wine, spicy and garlic), pork meatballs (original, shitake mushroom, and the newest flavor: taro), shrimp rolls, five spice meat rolls and pork-and-shrimp wontons.

When asked what sets her products apart, especially the 3,500 pounds of sausages they sell per month, Christine points to the texture. “The big difference between ours and other Taiwanese sausages is the way we cut our meat,” she says. “In Taiwan, they’ll grind everything. When you grind fat, it becomes kind of mushy, or greasy, rather than having its own distinctive texture. We cut our fat that goes into the sausage. … We have a machine only dedicated to cutting fat.”

As for what’s next for Hoja Foods, she says they are pursuing their USDA certification so that they can distribute to more restaurants and markets. She also says, “I want to preserve my family’s company while moving forward and modernizing.”

She could be speaking for all of these long-running Sacramento food products — “kruffles” and ravs as well. Let’s hope we can purchase all of these for decades to come.

–

Stay up to date on business in the Capital Region: Subscribe to the Comstock’s newsletter today.